Air steam hammer model M2145 Hammers Hammers EMTC Machinery

These machines named forging hammers, power hammers or pile drivers works by two cylinders, one at the back and another one at the front which is the one that impulses the stem for the stroke. The motor for the power hammer moves the rod of the back cylinder or compressor and the compressed air goes to the front cylinder through the valves that control the stroke displacement.

Hammer Machine at Rs 500000/unit Hammer Machine in Mumbai ID 12994855091

The board drop hammer is a drop forging machine tool that relies only on gravity. A hardwood board is attached to the ram, rollers grip the board and can raise the board and ram due to friction forces between the board and rollers. Once the ram is raised to the height needed, the rollers can be pulled apart and the apparatus will be released.

MASSEY Hammers Machine Hub

Forging & Foundry Machines - Forging Hammers for sale listings - We have 12 listings for Forging Hammers listed below. Find items by using the following search options. You can also click on the column heading to sort through the listings. For more information on an item, contact the seller directly.

closed die hammers and presses, open die hammer press and manipulator, steel ball

Forging and Pressing Foundry Machines. March 6, 2018. Forging and stamping is one of the most common metal processing technologies. The process of converting a semi-finished product (billet) into a final product can be carried out manually and mechanically. In the first case, forging hammers or sledge hammers of different weights are used.

C41 Series Pneumatic Hammer For Solid Sheet Metal Forming Press Machine

Equipment Hydraulic drop-hammer (a) Material flow of a conventionally forged disc; (b) Material flow of an impactor forged disc. The most common type of forging equipment is the hammer and anvil. Principles behind the hammer and anvil are still used today in drop-hammer equipment. The principle behind the machine is simple: raise the hammer and.

55kg Hammer Machine at Rs 250000/piece Hammer in Wadhwan ID 22494326888

Either a forging hammer or a forging press can be used in the forging processes. Operation of a Forging Hammer. Different parts of a typical forging hammer are shown in the picture above. (Click the image to enlarge.) The functions of the different parts are: Anvil: This is the rigid base of the forging hammer. The anvil holds the lower half of.

Hammers EBR Metal

press industry as the universal forming machine. For small to mid-sized series, it is an economical alternative to presses. Working capacity: 16 - 160 kJ. As the forging hammer works with a non-contact, electri-cally driven linear motor, the standard hydraulic drive head is no longer required. As such, the dynamically highly

Power Hammer Machine at Rs 350000/piece Hammer Machine in Ahmedabad ID

With more than 10,000 tools the hammers at Scot Forge can create small to medium size forgings quickly and cost-effectively, saving you time and money on manufacturing tools to forge your components. Pneumatic hammers consist of a frame, an anvil and a reciprocating ram holding a hammerhead or die. The billet is placed on the lower anvil or die.

Hammer Machine Loader Tractor Back Rear Manufacturer from Ahmedabad

Power hammers or drop hammers, as drop forging equipment is known, may use pneumatic, hydraulic, or electrical power. The dies and punches may be flat or V-shaped, and the striking force can range from 11,000 to 425,000 pounds (lbs). Because only one ram is needed to form the part, flash is produced and needs to be trimmed..

C4125 Blacksmith Power Hammer For Sale Machine Buy Machine,Blacksmith

WHAT IS A FORGING HAMMER? Forging is a manufacturing process involving the shaping of metal using localized compressive forces. The blows are delivered with a hammer (often a power hammer) or a die. Forging hammers are used in the drop forging to form the metal between two dies. The first half of the die is attached to the anvil and the second.

Our 16 ton presses are built with the small shop in mind, simply roll the press out when

80. 26162. 26162. If you would like to request a quote for one of our forging hammers for sale, for any other piece of machinery on our site, or for a machine you are searching for that is not on our site, please click on eMail us at or give us a call at . If you have any forging hammers or other types of machinery or equipment that is surplus.

hammer TMP Voronezh MA2147 — 5 ton (IDS79255)

3. Steam or Air Power Hammer. A steam-power hammer can be performed by either steam or compressed air. It includes a moving ram, rod, and piston, a lifting tool, a double-acting high-pressure steam cylinder, housing or frame, and anvil. In these types of forging power hammers, initially, steam is entering the bottom of the cylinder and the.

China Heavy duty C41150KG for metal electric power air Pneumatic Hammer China

From custom-built presses, auxiliary equipment, or remanufacturing projects, Ajax/CECO/Erie Press builds the industry's most reliable and efficient forging presses. With force capacities ranging from 500 to 15,000 U.S. tons, Ajax/CECO/Erie Press Hydraulic and Mechanical Forging Presses can be designed for closed die, isothermal, open die, and.

Blacksmith free machine air power hammer pneumatic open die hammer Power

Find Forging Hammer, 10000KG, 1000T, 150kg, 16000KG and other equipment for sale at ERS MANAGEMENT LTD. Home; Inventory. BORING MILLS AND MACHINING CENTERS.. Horizontal forging Machine/ UPSETTER. 1200T 1250T 2000T 250T 630T 800T. HOT STAMPING / FORGING PRESSES.

Pneumatic Hammer Machine at Rs 500000 Machinery in Mumbai ID 13073923288

Stock Up On Toolbox Essentials With Our Range Of Hammers - The Right Tool For Every Job. UK's Leading PPE Supplier Renowned For Our Great Customer Service. Buy Well. Buy Safely.

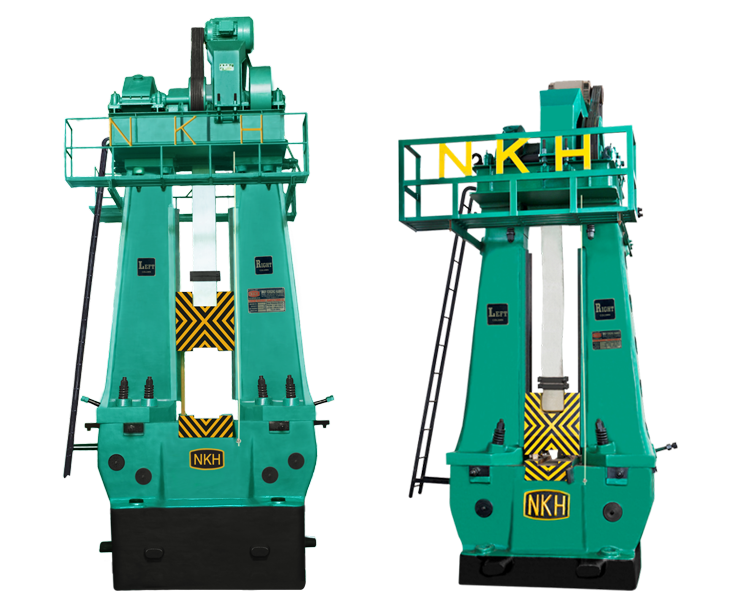

Drop Hammer NKH

1. Drop Forging. Drop forging may be a metal forming process. A workpiece is inserted into a die then hammered until it's assumed the form of the die. The lower die could be a stationary part, while the upper part may be a moving hammer dropped onto the workpiece so as to deform it. Drop forging are oftenperformed both at high or ambient.